Performance analysis and design optimisation for

COMMERCIAL SHIPS, SERVICE OPERATION VESSELS & WORK BOATS

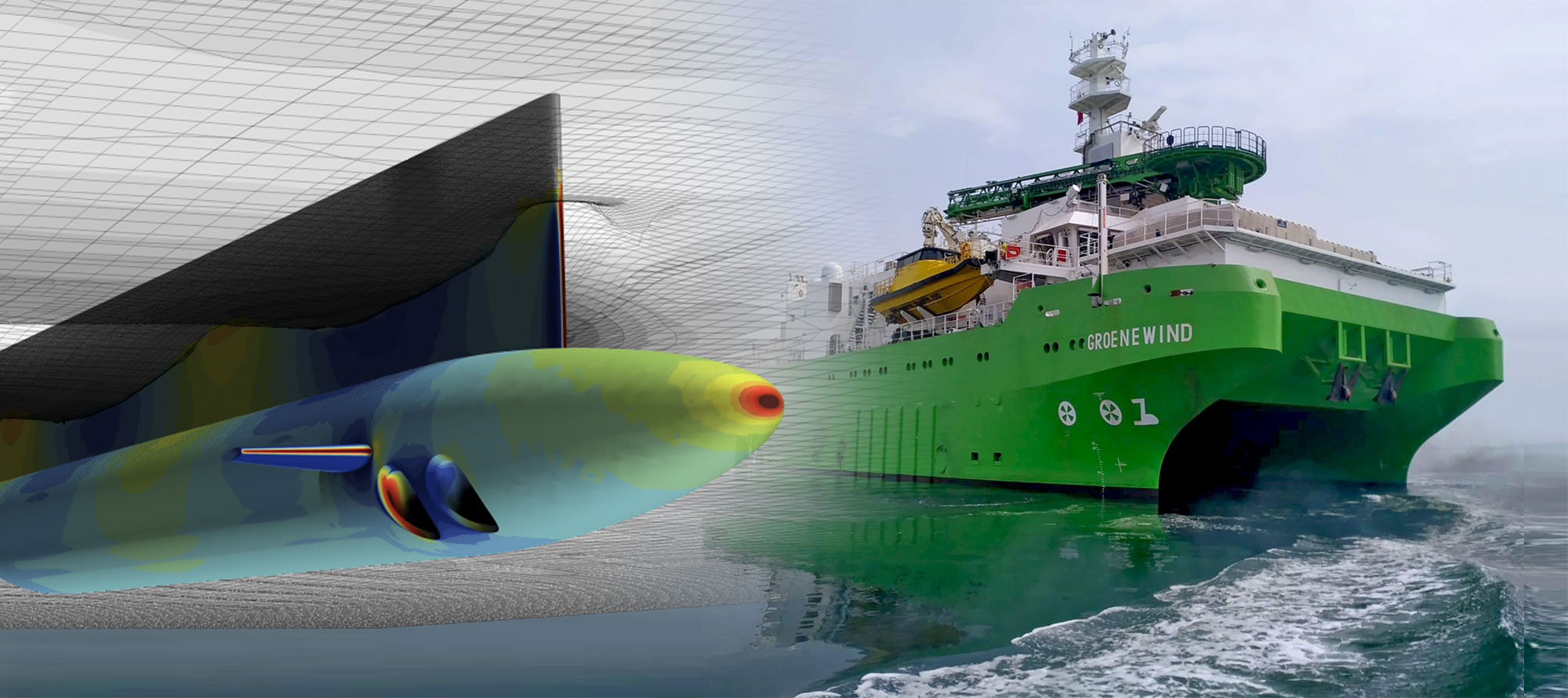

Cape Horn Engineering have pioneered RANSE based CFD since its very beginning and continues its research work on a daily basis. Due to our proven expertise in the America’s Cup, Volvo Ocean Racing and other high profile sporting events, we can apply this cutting edge technology to a wide variety of other marine applications including commercial cargo ships, service operation vessels, cruise ships, work boats , fully foiling and foil assisted high speed vessels, advanced and unconventional vessels, to improve performance, comfort and safety, increase energy efficiency, and to save fuel and reduce emissions.

Our specialist CFD technology and expertise is at the forefront of new design solutions to enhance energy efficiency in the shipping industry.

Using CFD Technology

We use advanced visualisation techniques to understand the flow features and to share that knowledge with clients. We post-process the simulations in a way that the designers obtain load cases and internal forces and moments for dimensioning the appendages of their designs. We carry out Fluid Structure interaction for appendages and sails. We assess cavitation in the appendages of all high speed craft. We have developed foil section optimisation loops that take into account transition and cavitation. For extensive design campaigns we optimise hull and appendage shapes using modern optimisation techniques like neural networks response surface models and optimisation algorithms.

Our CFD methods cover a large variety of flow behaviours and includes free-surface flow, viscous flow, full-scale performance prediction, fluid-structure-interaction and dynamic behaviour. We excel in what we do, in our engineering expertise, our passion to succeed, our attention to detail and our exclusive use of the best tools available. Our powerful resources are a guarantee for outstanding results delivered to support your project.