The Barcelona Yacht Design Group requested Cape Horn Engineering to analyse the resistance of the new 12m Monorquin motor yacht by means of state-of-the-art CFD simulations.

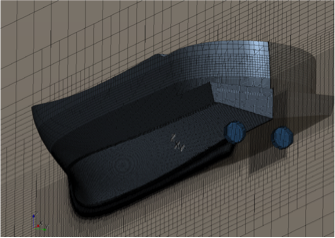

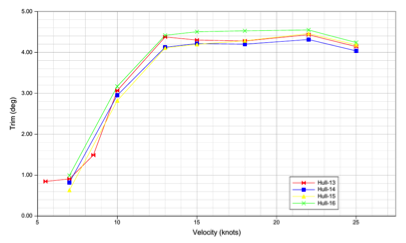

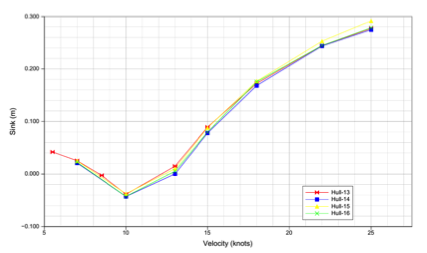

In this particular case study 4 different hull shapes were investigated at the full range of operational speeds. For these virtual towing tank tests the hull is free to sink and trim. The propellers are modelled with actuator disks and in this way the main effects of the propellers/hull interaction are considered.

These kind of studies are nowadays quite standard and easy to set up, not only for the CFD experts at Cape Horn Engineering but also for the clients commissioning the studies, who are just guided effortlessly through the process of providing the necessary inputs.

Thanks to the High Performance Cluster available to us and the automation of our processes, 4 different hull shapes can be analysed in less than 24 hours thus giving our clients a fast turn around from initial considerations to a final report.

The standard results that are included in the final report typically are:

- Resistance curve

- Dynamic sinkage and trim

- Wetted surface variation

- Pressure vs viscous forces

- Spray visualization

- Propeller intake flow analysis

For this particular case study the Hull 15 showed a consistent drag reduction (up to 4%) at cruising speeds (17 to 25 knots), see diagram below.