Cape Horn Engineering are extremely proud to be part of the development team involved with this exciting project and have already performed an extensive Computational Fluid Dynamic programme to improve the design and performance of the solid wings, as well as providing analytical evidence of potential savings.

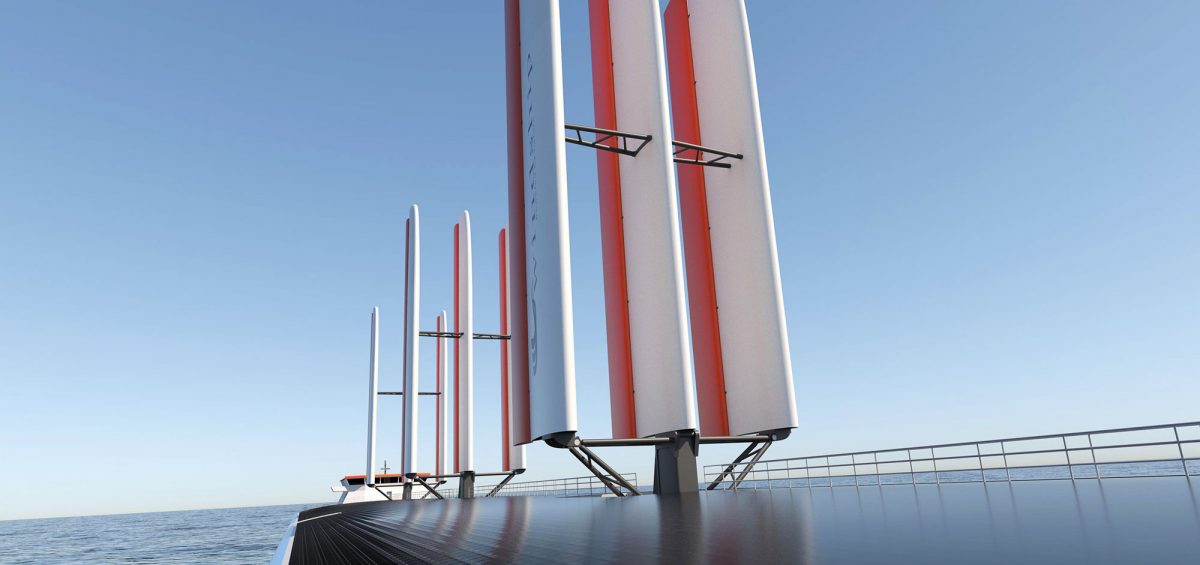

The distinctive triple-wing rigs produce a driving force several multiples greater than single masted solutions of the same height. The 48m Windship Technology rig is stowable on deck through a unique, innovative stowage solution to aid port navigation and cargo handling. Its composite structure is borne out of technology and design from the wind turbine industry, ensuring reliability and longevity of greater than 25 years. The system allows reductions in engine power to be made in order to achieve the same speed and so maximise fuel-saving and emissions reduction.

The Windship technical team have further developed a new diesel electric ship drive system that eliminates CO2, NOX, SOX and particulate matter to True Zero whilst also incorporating large solar arrays, carbon capture, optimised hull shapes and specialised weather routing software into the overall design package for a whole-ship, True Zero emission solution.

Further CFD design optimisation will take the Windship concept ship into consideration as a whole, including the ship hydrodynamics, engine and propulsion, aerodynamics and optimal routing. The operating conditions for the vessel will be the advance speed and the drift, heel and rudder angles. Furthermore, windage on superstructures and the added resistance due to sea state will be modelled and taken into account. The optimisation process and predicted potential performance will determine the optimal operational points resulting in the lowest required engine power, fuel consumption and total emissions.

Windship Technology announces new partnership

The new partnership with international registrar and classification society DNV will involve conducting both an outside-in and inside-out verification to fully assess Windship Technology’s whole-ship design with a view to classifying emission reductions, safety and operability.

Per Marius Berrefjord (Senior Vice President) of DNV commented: “We are delighted to be working with such experienced professionals at Windship Technology in a project which aims to help transform the entire shipping industry to True Zero. We will work closely with the project team in a fully transparent manner as we now initiate the work to establish a simulation model that will help us verify the GHG emission reduction capability of the technology. We are also preparing for a HAZID that shall verify the safety and operability of ships with Windship Technology installed. These activities will be followed by further verification activities as the project moves forward. Windship is supplying information in a fully transparent manner, and DNV will ensure a thorough verification process. We are looking forward to dive deeper into the very interesting technology presented by Windship.”

Against a backdrop of new build ship orders down over 50% in 2020, and regulators such as the International Maritime Organisation backed by the United Nations demanding environmental and sustainable reform from the industry, Windship Technology is offering a ‘Tesla of the Seas’ solution for shipping. The Windship Technology True Zero Emission solution is presently the only viable and most economical zero emission project for ocean-going bulk carrier and oil tanker ships.”