Cape Horn Engineering are delighted to have proudly worked as part of the specialist technical team for international yacht designer, Malcolm McKeon on Baltic Yacht 112 ‘Liara’. Her owners requirement was for a fast, easy to use, family yacht, designed for worldwide cruising and occasional racing. With this in mind, a powerful hull and optimum sailing performance, among many other features, were critical elements.

STRENGTH AND AERODYNAMICS

Weight saving was an important part of the design process, which has been achieved through her advanced carbon composite construction using foam and Nomex cores. Carbon fibre was a key part of the construction process, not just in the lightweight hull but also in the mast, boom and rigging, which provide an unbeatable combination of strength, aerodynamics and durability. The stylish cockpit roof and fixed bimini are also a carbon fibre lightweight structure, which will provide protection and shelter for guests in all weathers.

SPEED & MANOEUVRABILITY

Liara’s generous sail plan features a sloop rig and square top mainsail with powered inboom furling. The lifting keel with iron bulb provides a deep draft of 6.15m for powerful performance, combined with a high righting moment. Her retractable propulsion system will enhance her speed and manoeuvrability. This highly-tuned cruising yacht will gracefully show off her sleek lines and performance pedigree when she competes in regattas. The easy handling, responsive steering and perfect balance of the twin helms, combined with the long waterline and fine entry means the yacht will keep sailing fast with minimal effort – a testament to the design, engineering and expertise of all the specialists involved.

Cape Horn Engineering‘s long-standing association with Malcolm McKeon has provided an unparalleled synergy to the design process of each yacht. Since 2016, they have built up a trusted partnership, collaborating on CFD investigations for six superyachts to ensure the highest degree of performance, comfort, stability and safety. They are currently working together on two large sailing yacht projects. A green approach to projects, increasing fuel efficiency and reducing fuel omissions is also a key consideration, whilst advanced engineering solutions, ensure each yacht performs to its full potential.

CFD INVESTIGATION & ANALYSIS

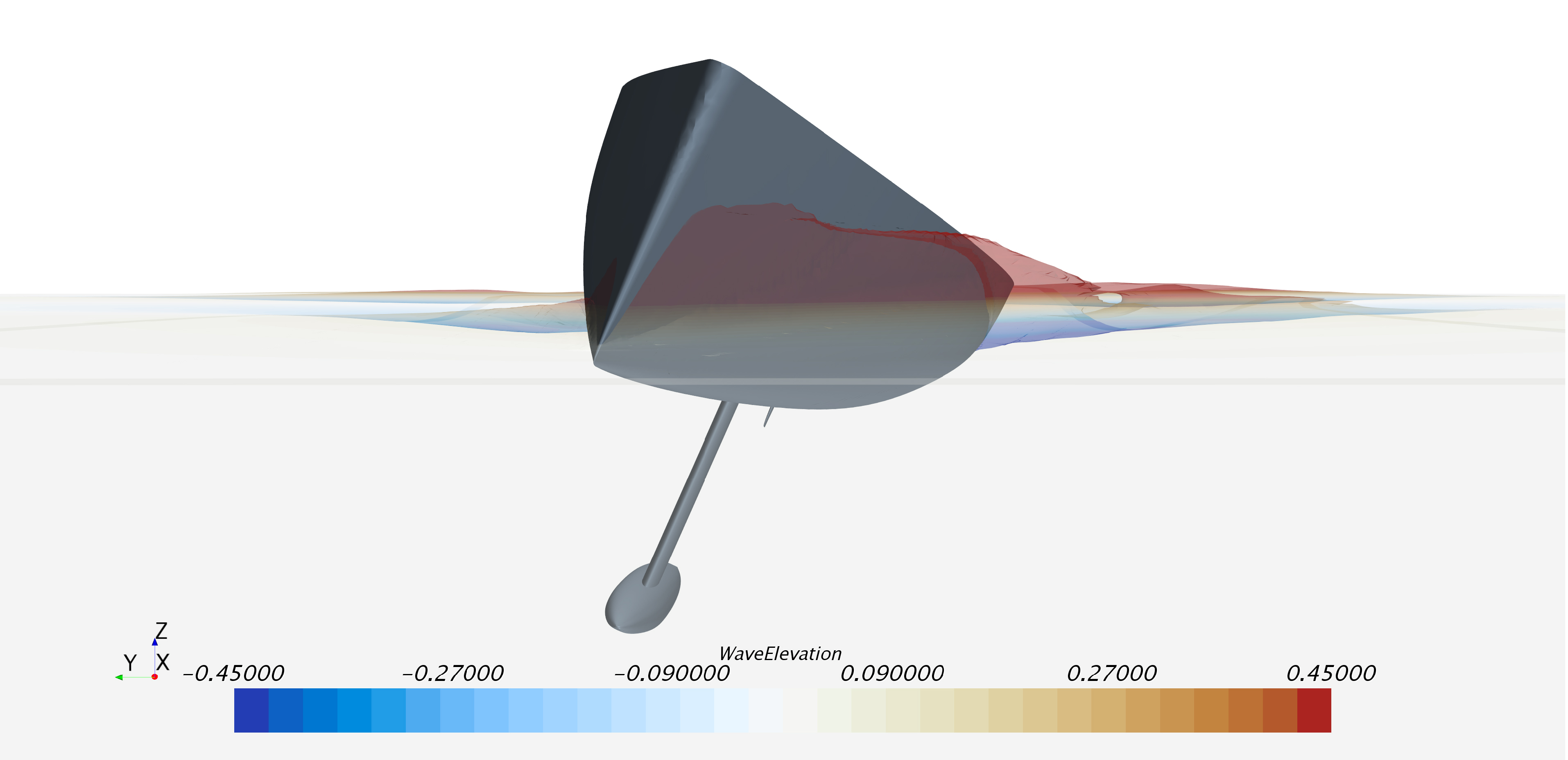

Once the initial concept for Liara was agreed, Cape Horn Engineering were commissioned to produce the data to ensure the performance met the design brief. The challenge of yacht design involves a continuing drive to develop and refine hull forms for improved efficiency in terms of streamlining profiles, weight savings and performance. Each design is taken through an extensive research and development program utilising sophisticated analytical tools to deliver optimum results. Computational Fluid Dynamics confirm performance prediction calculations and explore the benefits and limitations of different hull and appendage configurations.

The CFD investigation on Liara was conducted to evaluate the performance of the hull with five geometric variations including differing centres of effort and height/area of the sail plan. The performance comparisons for sail drive and retractable propulsion options were also explored. Simulations were carried at full scale with ‘2 Degrees of Freedom’ (sinkage and trim), free surface deformation, viscous and turbulent flow using the state-of-the-art software Star-ccm+ from Siemens PLM.

A large computational matrix of sailing conditions consisting of over 100 points was run for the baseline configuration and the alternative candidates, with variations of boat speeds, heel, leeway and rudder angles. This hydrodynamic data, forces and moments for each configuration, served as input for the Velocity Prediction Program (VPP).

AEROSIM PORTAL

Aerodynamic simulations of sails and rig were carried out by North Sails, using Cape Horn Engineering’s expertise and their unique AeroSim portal – an on line service which gives sail designers direct access to the most advanced and powerful CFD technology available. Jeremy Elliott, Head of North Sails Design Services brought the hydrodynamic and aerodynamic data obtained with CFD together into the North Sails’s VPP to analyse the potential performance of all the candidates and final yacht configuration in real wind and sea state conditions.